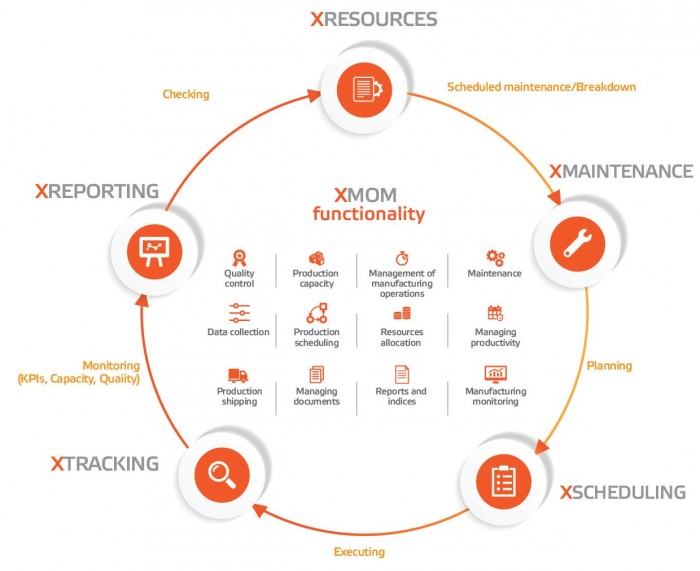

XMOM

The XMOM (Manufacturing Operations Management) system consists of 5 software modules that establish the connection between your ERP system and the production lines. XMOM helps employees at every level of the enterprise – from directors and managers to local operators – to make the right short-term and long-term decisions that improve the production cycle. Through powerful tools hidden behind an easy and intuitive web-based interface, the system enables you to create complex production schedules, monitor production processes in real-time, control and plan production capacity, and more.

XMOM is compatible with any ERP system regardless of the manufacturer, and its entire functionality is unified in an easy and intuitive interface that can be customized according to the client’s requirements.