Goals of the system

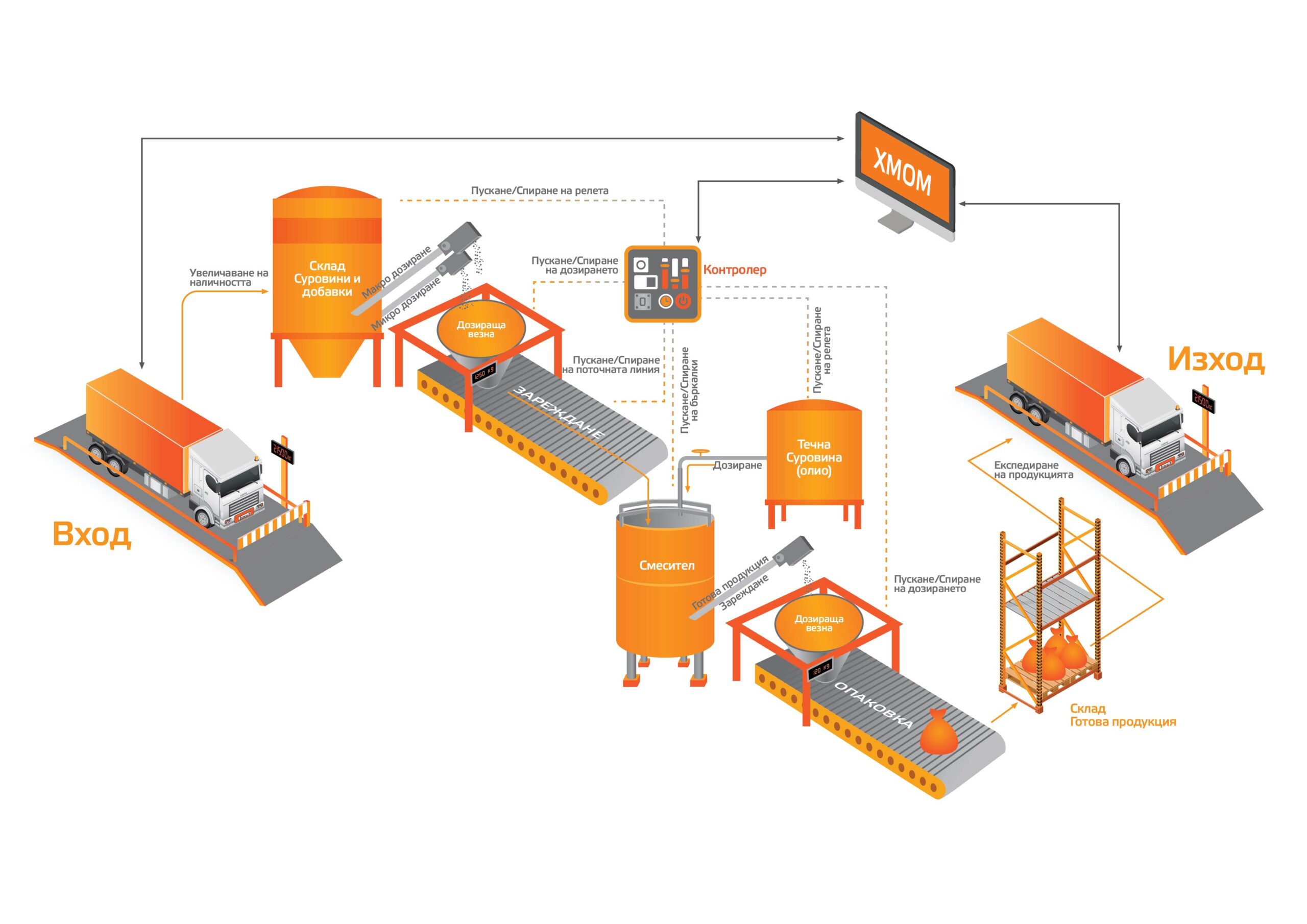

The goal of XMOM is to optimize and automate the management of the entire feed production process, from the receipt of raw materials, through their dosing, to packaging and dispatch.

Main problems which the system solves

- Difficult traceability of available resources and finished products

- Difficult traceability of the dosing process

- Manual dosing of raw materials, consuming a lot of time and increasing the chance of human error

- Inefficient tracking of movements of raw materials and finished products at the input and output of the enterprise

- Manual and inefficient production schedule planning, consuming a lot of time and increasing the chance of human error

- Difficult traceability of production and batches

Highlights

- Web-based system with responsive interface accessible from mobile devices and desktop computers

- Monitoring of the entire production process

- Optimization and automation of production schedule planning

- Automation of the entire raw material dosing process

- Automation of the finished product packaging process

- Automation in managing inventory levels

- Timely identification of resource shortages for production

- Visualization of detailed statistical data for the entire production process