Goals of the system

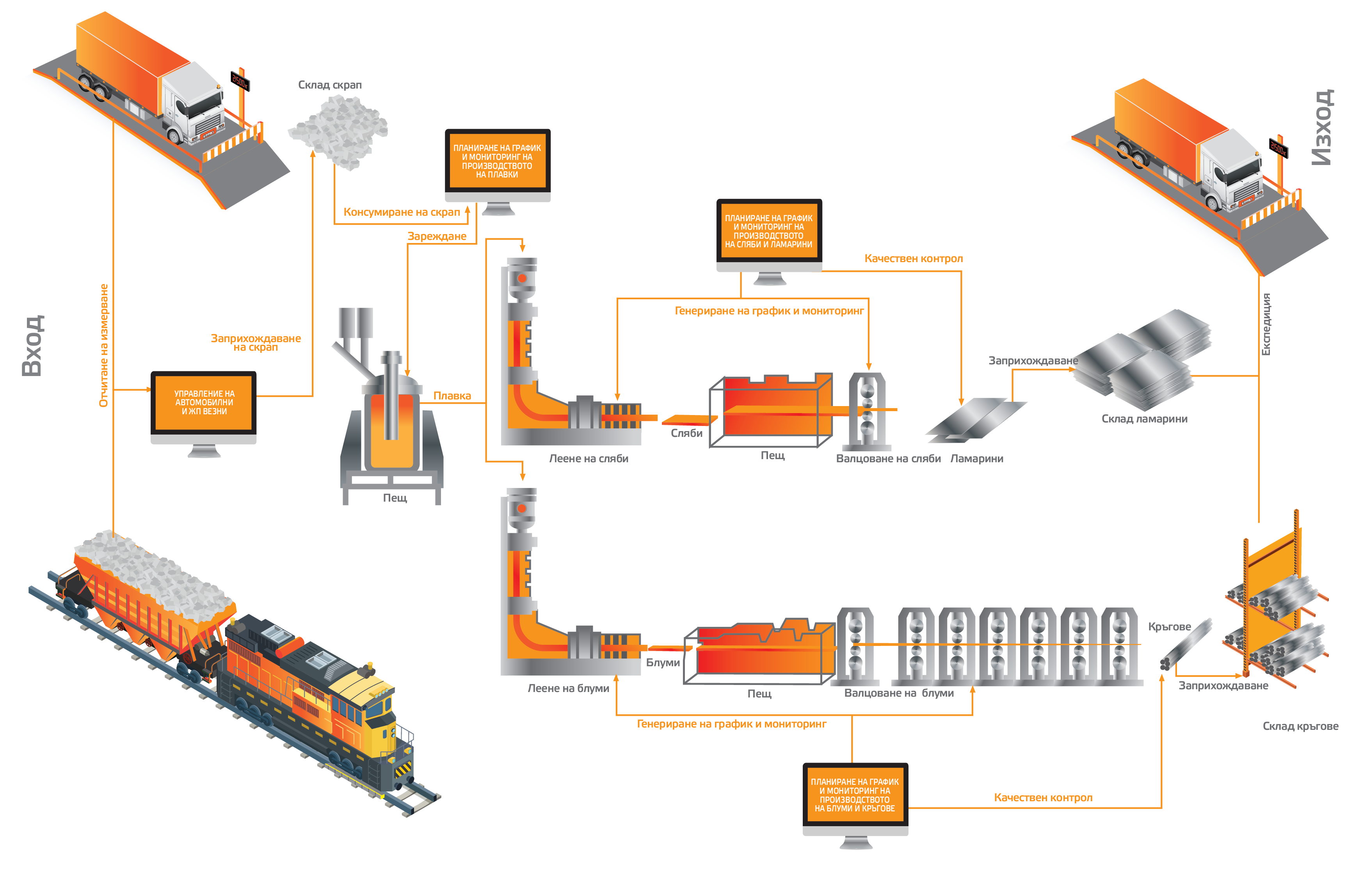

The goal of XMOM is to optimize and automate the management of the entire process of producing hot rolled steel sheets and round profiles – from scrap acceptance, through casting and production, to shipment.

Main problems that the system solves

- Real-time tracking of scrap inventory

- Generation of optimal production schedules in real time

- Real-time rescheduling of production schedules in emergency situations: equipment failure, new order, or change in order priority

- Real-time monitoring of production processes

Main highlights

- A web-based system with an adaptive interface that can be accessed from mobile devices and desktop computers

- Real-time tracking of scrap income and expenditure throughout the enterprise

- Monitoring of the entire production process

- Optimization and automation of production scheduling

- Timely identification of resource shortages for production

- Visualization of detailed statistical data for the entire production process