The smooth operation of machines and timely response to any malfunctions are fundamental to the efficient functioning of production facilities in any industrial enterprise. XMAINTENANCE provides a wide range of comprehensive tools for successful maintenance management in any production setting.

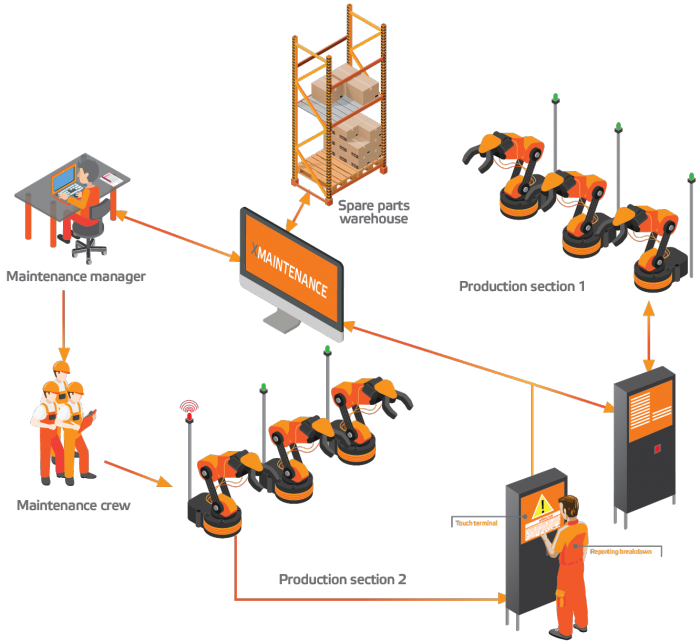

The main goal of the system is to improve processes and reduce the time required to detect, report, and resolve malfunctions in production areas, as well as facilitate preventive repairs and maintenance. Each machine can be connected to the system, and its operational status is visible in real-time. In the event of a malfunction, the maintenance manager receives immediate notification and information about the problem, enabling prompt action to address it.

Every registered malfunction and issue is recorded in the system for later analysis, as well as to accumulate statistical information on the most common malfunctions, repairs, and spare parts used. In the long run, this helps identify problematic areas in production and enables better preventive maintenance.

The strongest aspect of the module is the use of Predictive Maintenance. It relies on machine learning and data analysis to predict potential failures or equipment issues before they occur. Predictive maintenance begins with data collection from sensors and other sources that monitor the equipment’s condition. This data may include parameters such as vibrations, temperature, pressure, electrical signals, and others. The collected data is used to train machine learning models that analyze the signals and predict the probability of failure or issues in the future.

Its benefits include:

- Reduction of unexpected equipment downtime by predicting failures or issues. This reduces losses for the enterprise, increases its production capacity, and simultaneously lowers the cost of production.

- Optimization of maintenance activities – Predictive maintenance systems allow operators and engineers to plan and perform maintenance only when necessary, rather than based on a fixed schedule. This reduces maintenance costs and spare parts consumption while increasing process efficiency.

- Increased equipment lifespan – Early detection of problems and technical failures allows operators to take appropriate measures to prevent damages and extend the life of the equipment.

Functionalities

-

Faster response to problems or malfunctions in production

-

Improved preventive maintenance

-

Real-time information about all machines significantly reduces response time

-

Unified database with all machines, their parts, and documentation

-

Collection and analysis of statistical data on failures and repairs

-

Report on lost operational time due to malfunctions for each shift, machine, and production area.

Benefits

- Real-time monitoring of machine status

- Capability to report a malfunction and its type through a local touch terminal

- Tracking the quantities of spare parts for each machine

- Setting minimum stock levels for spare parts

- Notification of production events

- Calendar with notifications for improved preventive maintenance.