ERP system for

Goals of the system

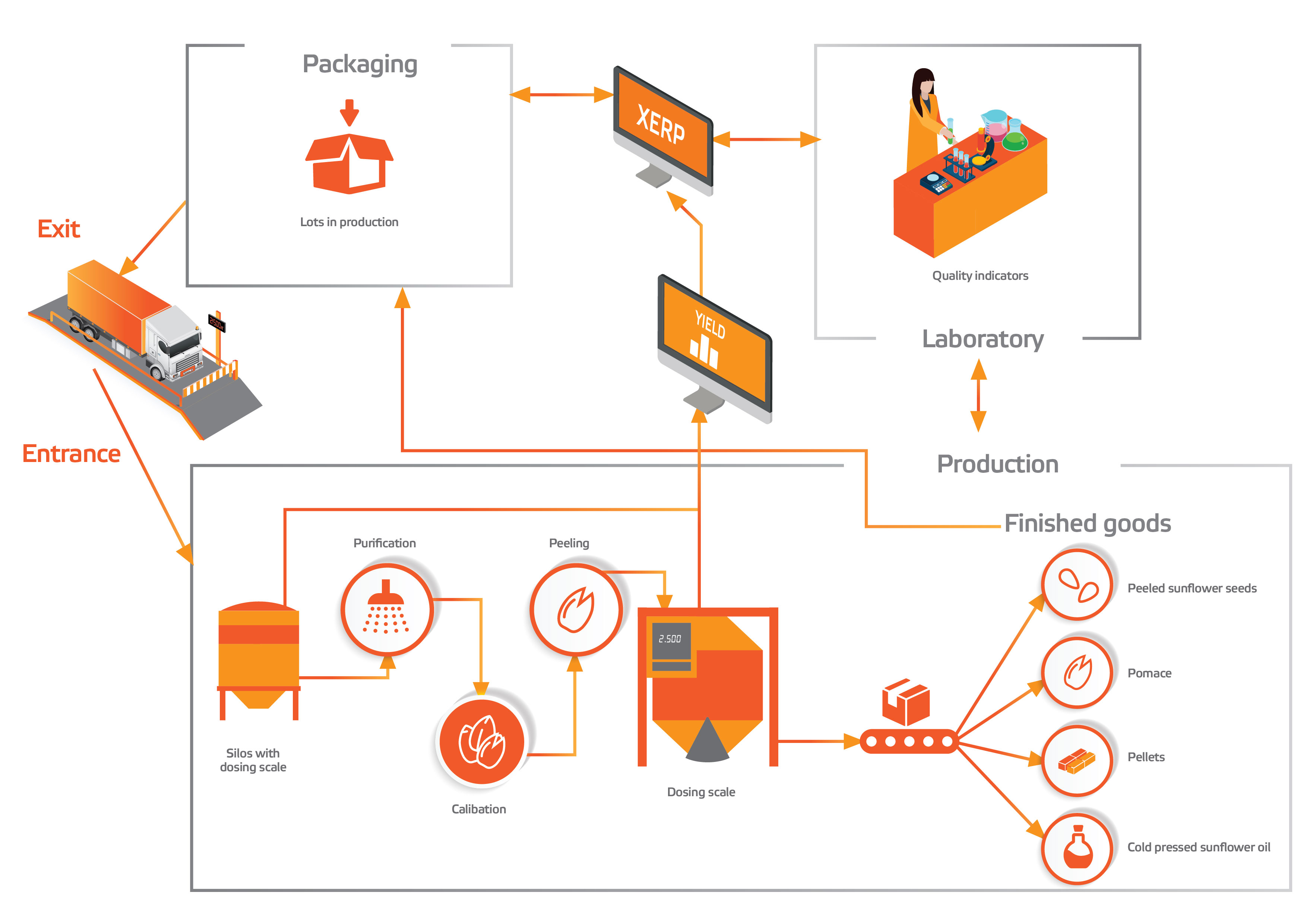

The Goal of the system is to optimize the work of agricultural producers and processors through automation of production, business and logistic processes

Main problems which the system solves

- Lack of real-time visualization of the yield

- Ineffective way of tracking the required monthly quantities for each client

- Ineffective monitoring of the entry and exit of goods from the plant

- Difficult tracking of the quality indicators and lack of historical data

Highlights

-

The real-time visualization of the yield helps to track the productivity of each shift

-

Easy and efficient way of tracking inbound and outstanding payments from clients through digitization of the accounting documents

-

Improved client relationship management;

-

Optimizing the quality control through digitizing the samples from different lots

-

Optimizing the processes of packaging and expedition through real-time information of the lots in production