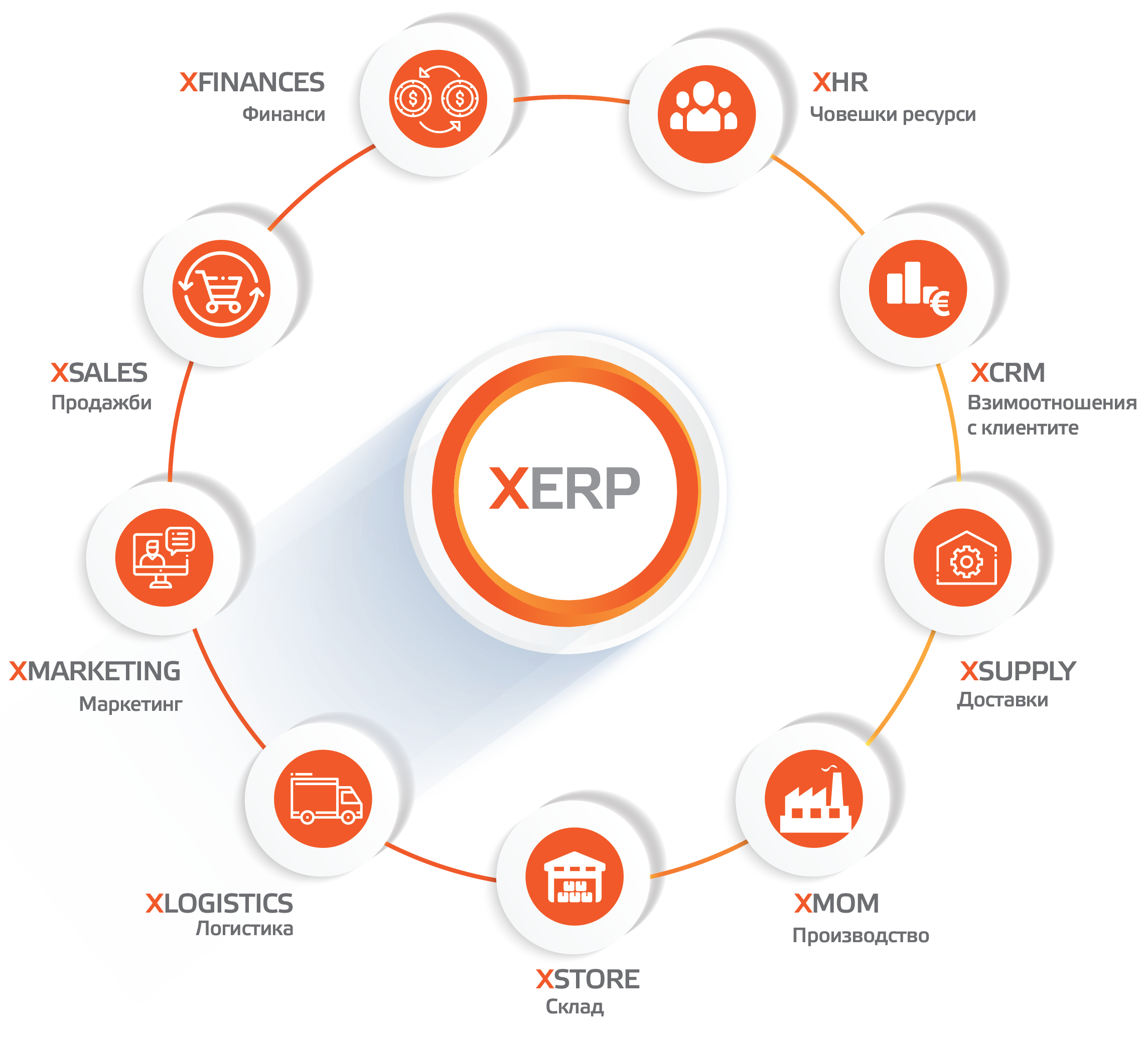

XERP

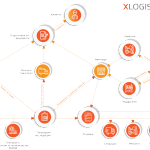

The production ERP (Enterprise Resource Planning) system by XSOFT – XERP – represents the integration of a wide array of corporate functions and tools necessary for the successful management of a manufacturing enterprise. They are subject to detailed customization and enhancement based on the processes of your company. XERP is a web-based system with an intuitive interface that allows users to work on both mobile devices and desktop computers. The main objectives of XERP are the optimization of the following processes:

- Planning and execution of production orders,

- Sales and marketing of end products and services,

- Analysis of business information and making short-term and long-term decisions.

The entire functionality of the system is consolidated into an easy and intuitive interface that can be adapted to the client’s requirements.

XERP provides a significant advantage to any manufacturing enterprise over its competitors, as it allows easy integration of personalized MOM and MES (XMOM) systems into XERP. This enables you to constantly adapt and improve the production cycle according to market conditions. This combination of functionalities and tools makes all work processes more transparent, improves efficiency, optimizes costs, and enhances the quality of work, which inevitably leads to greater revenue for the enterprise.